- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Kitajska Izostatični grafit Proizvajalci, dobavitelji, tovarna

- View as

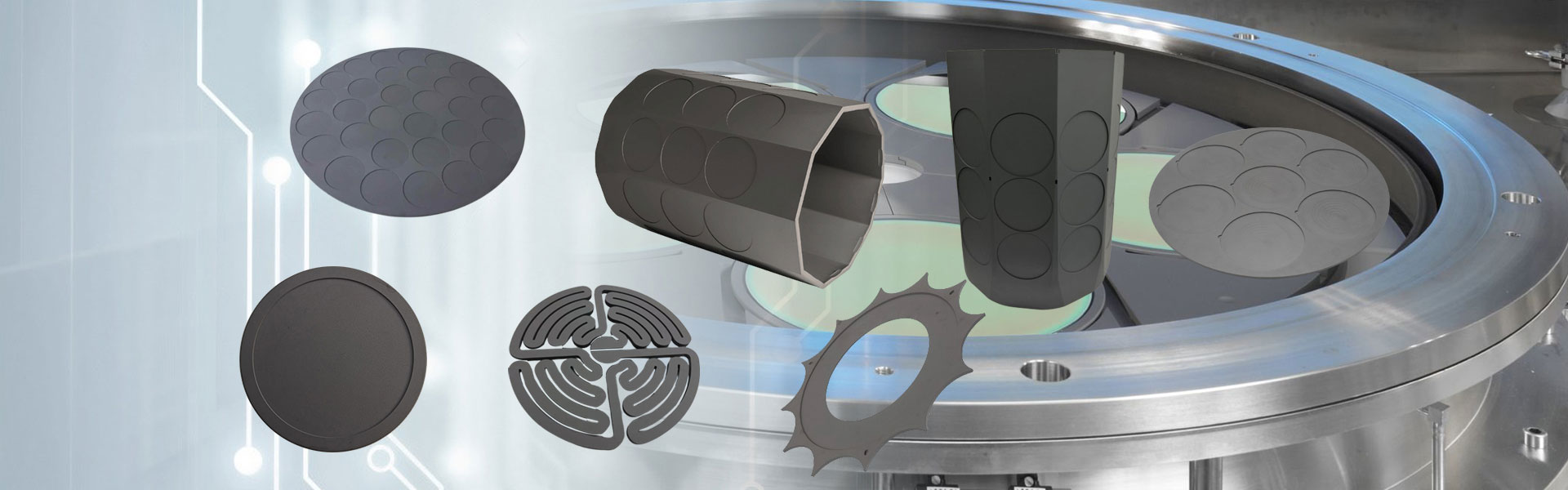

Samomazalni ležaji

Samomazalni ležaji Semicorex so vrsta ležajev, ki združujejo samomazalne lastnosti grafitnih materialov. Široko se uporabljajo na industrijskih področjih z visokimi zahtevami po mazanju in zapletenimi okoljskimi pogoji.

Preberi večPošlji povpraševanjeGrafitni grelec palice

Semicorex Graphite palice je visokozmogljiv ogrevalni element, zasnovan za enotno visokotemperaturno generacijo znotraj vakuumskih pečev. Izberite Semicorex za njegovo strokovno znanje na področju natančno opremljenih grafitnih rešitev, ki zagotavljajo vrhunsko toplotno stabilnost in dolgotrajne zmogljivosti, prilagojene vašim industrijskim potrebam.***

Preberi večPošlji povpraševanjeGrafitna elektroda palica

Semicorex Graphite Elektrode palice so komponente z visoko čisto čistostjo, ki se uporabljajo kot jedrne ogrevalne elemente v vakuumskih pečeh. Izberite Semicorex za neprimerljivo kakovost materiala, natančno obdelavo in zanesljive zmogljivosti v vakuumskih okoljih visokotemperature.*

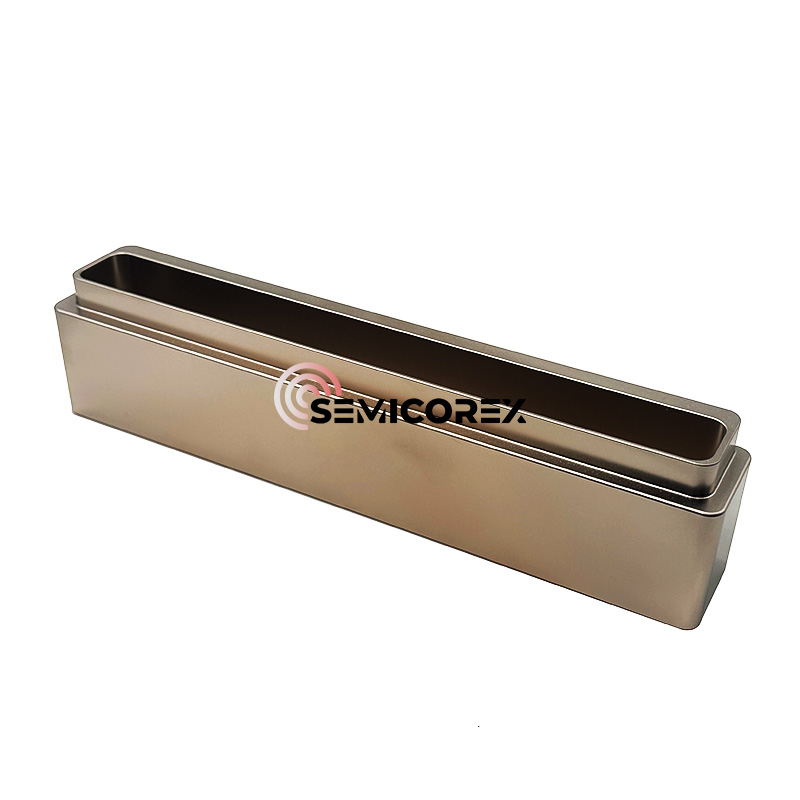

Preberi večPošlji povpraševanjeGraphite Top Plošče

Porekovane grafitne zgornje plošče so natančno opremljene napeljave, zasnovane za varno in zanesljivo ravnanje s steklenicami vročega stekla v visokotemperaturnih proizvodnih okoljih. Izberite Semicorex za neprimerljivo kakovost materiala, zmogljivosti obdelave po meri in dosledne zmogljivosti, ki jim zaupajo vodilni proizvajalci stekla po vsem svetu.*

Preberi večPošlji povpraševanjeGrafitni lončki

Polmočne grafitne lončke, zasnovane za izjemno toplotno stabilnost in nadzor kontaminacije v procesih rasti polprevodniških kristalov. Izberite naše grafitne lončke za neprimerljivo čistost, zmogljivost in zanesljivost pri rasti polprevodniškega kristala. *

Preberi večPošlji povpraševanjeGraphite Chuck

Semicorex Graphite Chuck je ključna sestavina v proizvodnji polisilicona, ki se pogosto uporablja v sončni industriji. Ko se povpraševanje po silicijevih rezinih z visoko čistostjo povečuje, je potreba po visokozmogljivih orodjih za obdelavo, kot so grafitni chucks, postala bistvena. Naši grafitni chucks, izdelan iz specialnega grafita, so zasnovani tako, da prenesejo ekstremne temperature, kemično izpostavljenost in mehanske napetosti, hkrati pa ohranjajo dimenzijsko stabilnost.***

Preberi večPošlji povpraševanje